Unique challenges bring out the best in our engineers.

Our expertise lies in the production of bespoke or custom designs, from the most basic individual incineration system, right through to large-scale turnkey engineered plants. Our ability to design and engineer equipment to suit our client’s exacting standards and requirements has lead to the manufacture of many unique facilities and installations in remote and often difficult locations, with extremes from the ice caps of the South Pole to hotter climates, such as the South Pacific.

Our wide network of customers includes hospitals and clinics, abattoirs, laboratories, veterinary and research establishments, pharmaceutical companies, pet crematoria, agricultural establishments, government departments, security and defense organizations, oil exploration companies, NATO/UN, airports, seaports, and labor work camps. In fact, the Surefire range of incinerators, cremators, and combustion systems are used wherever there is a requirement for the destruction/treatment of solid and liquid wastes.

Developing A Tailored Solution

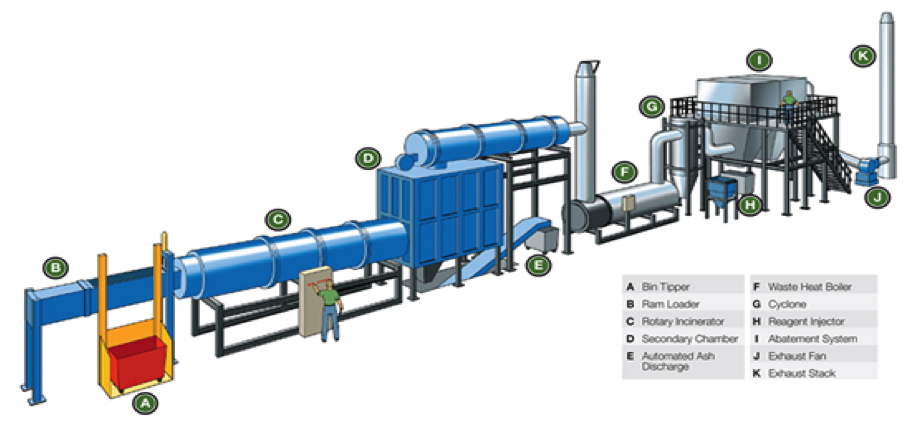

Meeting a unique incineration challenge begins with a thorough analysis of your specific need, from the type and volume of waste to the way it is transported to the incinerator. Our carefully tailored solution will very likely involve configuring all of these options:

-

Loading and Feed Systems

Loading waste into the primary combustion chamber can be carried manually or automatically, depending on the capacity of the plant and the nature of the waste. Loads exceeding the capacity are generally considered unsafe and operationally/environmentally inefficient. Bagged waste weighing up to 200kg can be manually loaded into the incinerator. Anything above 200kg should be automatically loaded. Matthews manufactures a full range manual and automatic loading systems, including bin tippers, elevators, container handlers, ram loaders, crushers, conveyors, and sludge/liquid feed systems.

Loading waste into the primary combustion chamber can be carried manually or automatically, depending on the capacity of the plant and the nature of the waste. Loads exceeding the capacity are generally considered unsafe and operationally/environmentally inefficient. Bagged waste weighing up to 200kg can be manually loaded into the incinerator. Anything above 200kg should be automatically loaded. Matthews manufactures a full range manual and automatic loading systems, including bin tippers, elevators, container handlers, ram loaders, crushers, conveyors, and sludge/liquid feed systems. -

Secondary Combustion Chamber

This is where waste in the gaseous phase is treated. Combustion gases that are given off in the primary chamber are transferred into the secondary chamber through a refractory lined duct. Additional combustion air is added at the inlet of the secondary chamber, and additional heat is provided by an afterburner. Air jets induce turbulence which mixes the combustion products with heat and combustion air. This process reduces the partial combustion products (carbon monoxide) and contaminant combustion products (volatile organic compounds and nitrogen oxides) to a minimum.

This is where waste in the gaseous phase is treated. Combustion gases that are given off in the primary chamber are transferred into the secondary chamber through a refractory lined duct. Additional combustion air is added at the inlet of the secondary chamber, and additional heat is provided by an afterburner. Air jets induce turbulence which mixes the combustion products with heat and combustion air. This process reduces the partial combustion products (carbon monoxide) and contaminant combustion products (volatile organic compounds and nitrogen oxides) to a minimum. -

Energy Recovery Systems

Gases that exit the secondary chamber can be ducted directly into a waste heat boiler which converts gaseous energy into useful energy such as hot water or steam. These boilers are constructed to the latest applicable standards and are heavily insulated and clad in aluminium. Control and safety features include level gauges, level switches, safety valves, crown valves, blow down valves and pumps.

Gases that exit the secondary chamber can be ducted directly into a waste heat boiler which converts gaseous energy into useful energy such as hot water or steam. These boilers are constructed to the latest applicable standards and are heavily insulated and clad in aluminium. Control and safety features include level gauges, level switches, safety valves, crown valves, blow down valves and pumps. -

Flue Gas Abatement

For compliance with the EU Waste Incineration Directive 76/2000, exhaust gases can be directed through a dry gas abatement plant. This comprises of a bag or ceramic filter house and a storage/feed system for the sodium bicarbonate and activated carbon system. Gases that exit the energy recovery plant are injected with lime or sodium bicarbonate and activated carbon that are stored in containers or silos which lie adjacent to the gas cleaning system. The lime/sodium bicarbonate reacts to neutralise acid components found in the gas, including sulphur dioxide and hydrogen chloride, while the carbon absorbs heavy metals and any dioxins.

For compliance with the EU Waste Incineration Directive 76/2000, exhaust gases can be directed through a dry gas abatement plant. This comprises of a bag or ceramic filter house and a storage/feed system for the sodium bicarbonate and activated carbon system. Gases that exit the energy recovery plant are injected with lime or sodium bicarbonate and activated carbon that are stored in containers or silos which lie adjacent to the gas cleaning system. The lime/sodium bicarbonate reacts to neutralise acid components found in the gas, including sulphur dioxide and hydrogen chloride, while the carbon absorbs heavy metals and any dioxins. -

Supervisory Control Systems

All incineration and cremation plant, including energy recovery systems and gas abatement systems, are controlled by a supervisory human machine interface. This innovative system continuously monitors plant performance and automatically trims and corrects any out of tolerance parameters. Used together with the emission monitoring package, the supervisory control system records, reports and archives emissions (including NOx, SO2, HCI, Particulates, CO, O2, H20 & TOC) which are released into the atmosphere.

All incineration and cremation plant, including energy recovery systems and gas abatement systems, are controlled by a supervisory human machine interface. This innovative system continuously monitors plant performance and automatically trims and corrects any out of tolerance parameters. Used together with the emission monitoring package, the supervisory control system records, reports and archives emissions (including NOx, SO2, HCI, Particulates, CO, O2, H20 & TOC) which are released into the atmosphere. -

Containerized and Mobile Incinerators

We design and manufacture a diverse range of containerized and mobile incinerators for use on remote and/or temporary sites. They can be simple skid mounts, or fully enclosed, self-contained portable incineration systems.

We design and manufacture a diverse range of containerized and mobile incinerators for use on remote and/or temporary sites. They can be simple skid mounts, or fully enclosed, self-contained portable incineration systems.